What is the Tarantula 3D Printer

The Tarantula 3D printer is a popular and affordable option for those venturing into the world of 3D printing. Often manufactured by Anet, this FDM (Fused Deposition Modeling) printer has gained notoriety for its accessibility, making it an excellent entry point for beginners. With an open-frame design and relatively simple mechanics, the Tarantula offers a great platform for learning and experimentation. This means it constructs objects layer by layer by melting and extruding thermoplastic filaments. Furthermore, its cost-effectiveness makes it an ideal choice for hobbyists, students, and anyone looking to explore 3D printing without a huge investment. The Tarantula’s open-source nature fosters a strong community, providing ample resources, upgrades, and support, ensuring help is readily available.

Features of the Tarantula 3D Printer

The Tarantula 3D printer comes with several features that make it a compelling option for beginners. It typically boasts a decent build volume, allowing for the creation of moderately sized objects. Features such as a heated bed are common, which helps improve print adhesion and reduce warping, ensuring your prints stick to the bed. Many Tarantula models include a built-in LCD screen and control knob, simplifying the process of navigating menus and initiating prints. The frame, often made from aluminum extrusions, contributes to the printer’s stability. While not always included, some models may feature auto-leveling capabilities, further streamlining the setup process. The combination of these features offers a solid foundation for learning and experimenting with 3D printing. Remember that specific features can vary depending on the exact model, so always check the product specifications.

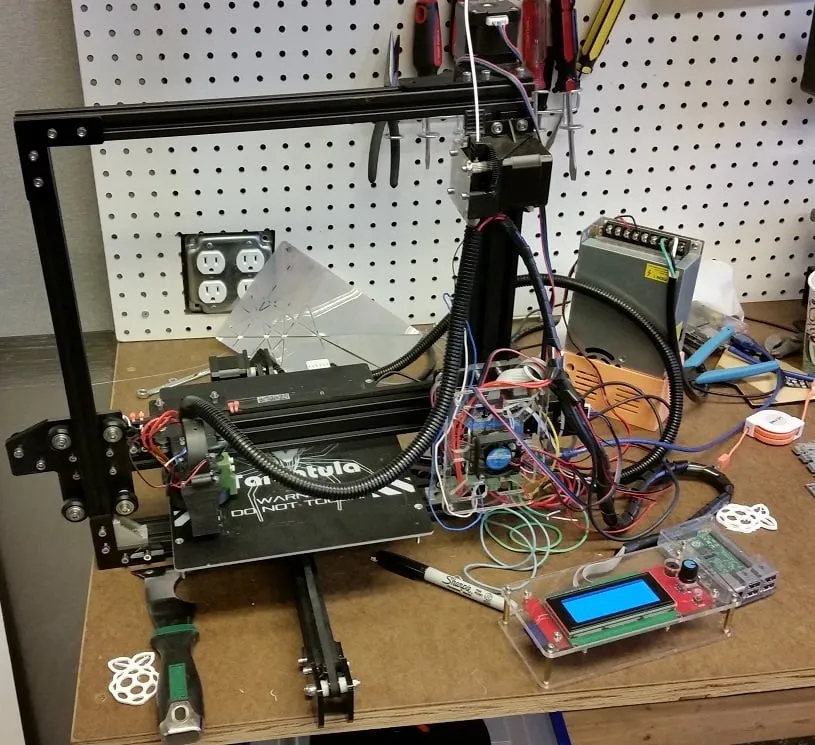

Unboxing and Setup of the Tarantula 3D Printer

Unboxing your Tarantula 3D printer is the first step toward 3D printing. Upon opening the box (image tarantula-3d-printer-unboxing.webp), you’ll find components carefully packed, including the printer frame, electronic components, and various accessories. Take inventory of all the parts using the included checklist to make sure everything is present. Place the components on a clean, flat surface, such as a table or workbench. Carefully organize the components for the assembly process. Following the instructions will lead to a successful build. Set aside some time, as assembly can take a few hours, depending on your experience. The included manual is generally easy to follow, but online videos can provide visual guidance. Double-check all connections and tighten screws securely to ensure stability and prevent any potential issues during printing.

What’s in the Box

Inside the box, you’ll find essential components necessary for 3D printing. These often include the printer frame, which provides the structural support for the build platform and other moving parts. You’ll also find the heated bed, where the 3D prints are built upon. The extruder assembly, responsible for melting and extruding the filament, will be present, along with the nozzle. Electronic components such as the mainboard, stepper motors, and power supply are key elements. A small set of tools like hex wrenches and screwdrivers are usually included to aid in the assembly process. Additionally, you’ll typically find an LCD screen and control knob for navigating the printer’s menu. The package usually has a sample filament roll, along with necessary cables, such as a USB cable, to connect the printer to your computer. It is important to carefully check all the items, compare them with the parts list, and make sure you have all the required components.

Assembling the Printer

Assembly is a crucial part of setting up your Tarantula 3D printer (image tarantula-3d-printer-assembled.webp). Begin by attaching the frame components, ensuring they are square and secure. Next, install the heated bed and the Z-axis components, which control the vertical movement. Mount the extruder assembly and connect the hot end. Carefully attach all the stepper motors and connect them to the mainboard. Follow the instructions to route the wires and connect the LCD screen and power supply. Tighten all screws to ensure stability. Double-check all connections before powering on the printer. Some adjustments might be necessary to ensure smooth movement of the axes. Refer to the manual or online tutorials for detailed instructions and visual aids. If you have a friend who already knows how to build a 3D printer, it would be helpful to ask for some assistance.

Connecting to the Printer

Connecting your Tarantula 3D printer involves several steps. First, you’ll need to connect the power supply to the printer and plug it into a wall outlet. Next, you’ll connect the printer to your computer using a USB cable. Install the necessary drivers on your computer, which usually can be found on the manufacturer’s website or the included USB drive. Ensure that the printer is recognized by your computer. For some models, you can also use an SD card to transfer print files. Once the printer is connected, you can use software like Repetier-Host or Cura to control the printer and send print commands. Always double-check the connections and ensure that the power supply is properly grounded. With the printer connected, you can now begin the software setup to prepare for your first print.

Software Setup for Tarantula 3D Printer

Setting up the software is an essential part of the 3D printing process. You’ll need two main types of software to get started: slicing software and printer control software. Slicing software converts your 3D models into instructions that the printer can understand (image tarantula-3d-printer-slicing.webp). This is where you define print settings such as layer height, infill density, and temperature. Popular slicing software options include Cura, PrusaSlicer, and Simplify3D. Printer control software allows you to send the sliced G-code files to the printer and monitor the printing progress. Repetier-Host and Pronterface are commonly used control software options. Install both the slicing and control software on your computer. Configure the software with the correct printer profile for your Tarantula model. Make sure you understand the settings and how they affect your prints. Practice slicing simple models and test your configurations before attempting complex projects.

Slicing Software Explained

Slicing software is a vital component of the 3D printing workflow. Its main role is to convert a 3D model (usually in an STL or OBJ file format) into G-code, which is a set of instructions that the 3D printer will follow to create the object. The slicing process involves several key steps. First, the model is imported into the software. Then, the software orients the model on the virtual print bed. The user then defines print settings such as layer height, infill density, print speed, and temperature, and other parameters that influence the final outcome. After defining the settings, the software “slices” the 3D model into thin horizontal layers. It then generates toolpaths for the printer’s nozzle to follow, depositing filament layer by layer. Understanding these settings is critical to achieve successful prints, and you may need to experiment with different settings to optimize quality and print time.

Configuring Slicing Settings

Configuring the slicing settings is crucial for print quality and success. You’ll need to configure various parameters in your chosen slicing software. These parameters will be adjusted depending on the type of filament and desired print outcome. Common settings include layer height, which affects the detail and smoothness of the print. A lower layer height results in finer details but can increase print time. Infill density determines how solid the interior of your print is. Higher infill provides strength but uses more material. Print speed influences how fast the printer moves, and it affects the print time. Nozzle temperature needs to be set according to the type of filament being used. The bed temperature ensures proper adhesion. Other settings to consider include support structures, which are needed to print overhangs, and the use of a brim, which helps to improve bed adhesion. Always start with the recommended settings for your filament and adjust as needed.

First Print Guide on Your Tarantula 3D Printer

Printing your first model is an exciting milestone (image tarantula-3d-printer-first-print.webp). Begin by selecting a simple 3D model. Popular choices for beginners include calibration cubes or small figurines. Prepare the model by slicing it in your chosen software with appropriate settings. Once the G-code is generated, save it to an SD card or transfer it to your printer via USB. Next, preheat the printer’s nozzle and bed to the correct temperatures for your chosen filament. Load the filament into the extruder. Ensure the bed is level to ensure proper adhesion. Select the G-code file from the printer’s LCD screen or from the control software on your computer. Start the print and monitor the progress. Observe the first few layers to ensure they adhere to the bed. Be patient, and don’t be discouraged if the first attempt has some imperfections.

Loading Filament

Loading the filament is a straightforward but essential step (image tarantula-3d-printer-loading-filament.webp). Start by preheating the extruder to the temperature recommended for the filament you are using (PLA, ABS, etc.). Cut the filament end at a 45-degree angle to help it feed smoothly. Insert the filament into the extruder, either manually or using the printer’s feed function. Gently push the filament through the extruder until it reaches the hot end. Ensure the filament flows from the nozzle smoothly. If the filament does not extrude, check for a clog in the nozzle or adjust the temperature. If the filament is loaded correctly, it will extrude when the printer starts printing. Regularly inspect the filament to confirm that it has been loaded successfully.

Leveling the Bed

Leveling the bed is a crucial step for achieving good first-layer adhesion (image tarantula-3d-printer-leveling.webp). Proper bed leveling prevents warping and ensures that the first layer sticks properly to the bed. Most Tarantula printers have manual leveling, so you will have to use the adjustment screws to level the bed. To level the bed, you’ll typically use a piece of paper between the nozzle and the bed. Move the nozzle to each corner and adjust the screws until the nozzle lightly grips the paper as you move it. Ensure that the nozzle is the same distance from the bed across the entire surface. Some models have auto-leveling features that use sensors to assist with this process. Regardless of the leveling method, this step must be performed properly every time you print.

Printing Your First Model

Once the filament is loaded and the bed is leveled, you are ready to print (image tarantula-3d-printer-first-print.webp). Load the G-code file onto the printer. Start the print from the printer’s control panel or from the control software. Monitor the first layer closely to ensure good adhesion. Check for any issues such as the filament not sticking to the bed or the nozzle dragging across the print. Watch for any other errors during the printing process. Be patient; the first print might take some time depending on the model’s complexity. Once the print is complete, carefully remove the model from the bed. You can use a spatula or scraper to assist. Examine the print for any imperfections. Make notes and consider those as you go through the troubleshooting steps. The first print is always an exciting experience.

Troubleshooting Common Printing Issues

3D printing can sometimes present challenges, but most issues can be resolved with basic troubleshooting. Common problems include poor bed adhesion, filament problems, and nozzle clogging. Understanding how to diagnose and fix these issues is crucial for a good printing experience. When troubleshooting, start by identifying the specific problem you are facing. Then, consult online resources, forums, and the printer’s manual for assistance. The 3D printing community is a valuable resource. Keep detailed notes about the settings and the issues encountered to refine the printing process. With a little practice, you will be able to solve any problems. By taking the time to troubleshoot, you can learn the ins and outs of your printer.

Filament Problems

Filament issues can lead to printing problems. Some common issues are filament jams in the extruder or hot end, which can be caused by a variety of reasons. Ensure that the filament is compatible with your printer and stored properly to prevent moisture absorption. Moisture can degrade the filament and cause printing issues. If the filament is brittle, it could be old, and you should replace it. When the filament gets tangled, the extruder cannot pull the filament. To solve the problem, check the spool for tangles and manually feed the filament into the extruder. Regularly inspect your filament for signs of damage or quality issues.

Bed Adhesion Issues

Poor bed adhesion is a frequent problem in 3D printing. If the print does not stick to the bed, the object can detach, leading to printing failure. To improve adhesion, ensure the bed is level. Adjust the bed temperature to the proper setting for your type of filament. Increase the initial layer height. Another method involves using a bed adhesive, such as glue stick, tape, or a specialized 3D printing bed surface. Check that the first layer is being extruded at the right height. Additionally, cleaning the bed surface is a great approach to ensure any dirt, oil, or other contaminants are removed. If these methods do not work, consult online resources for further solutions. Troubleshooting these adhesion problems will help to minimize failures.

Nozzle Clogging

Nozzle clogging can also cause printing problems. Clogging prevents the extrusion of filament, so it is important to solve the problem. It can be caused by several reasons, including overheating or using incorrect temperature settings, debris in the filament, or even the accumulation of degraded filament in the nozzle. One method is to clean the nozzle using a needle or a specialized tool. Another option is to perform a “cold pull,” which involves heating the nozzle, then manually extruding the filament after it has cooled. It is recommended to replace the nozzle if it has become excessively clogged. Prevent future issues by maintaining proper filament storage and ensuring the print temperatures are correct for the filament you are using (image tarantula-3d-printer-nozzle-cleaning.webp).

Maintenance Tips for Your Tarantula 3D Printer

Regular maintenance is essential for keeping your Tarantula 3D printer in good working condition. By following the maintenance recommendations, you can improve the printer’s lifespan and performance. Routine maintenance prevents potential problems and ensures that the printer continues to produce high-quality prints. Make a habit of performing a few checks after each print or every few prints. Take the time to clean and inspect your printer regularly. This investment of time and effort will pay off by minimizing the risk of breakdowns and ensuring that your printer is always ready to print. These maintenance tasks are generally easy to perform and take little time.

Cleaning the Nozzle

Cleaning the nozzle is a crucial maintenance task (image tarantula-3d-printer-nozzle-cleaning.webp). Debris, such as bits of filament, can accumulate in the nozzle, leading to clogs. To clean the nozzle, heat it to the appropriate temperature for the filament used. You can use a needle or a specialized tool to clear any blockages. Another cleaning method involves performing a “cold pull,” which involves heating the nozzle, then manually extruding the filament. You should carefully monitor the nozzle to check whether filament comes out easily. A clean nozzle guarantees smooth and consistent filament extrusion. Cleaning the nozzle regularly is essential to maintain printing quality.

Lubricating Moving Parts

Lubricating moving parts prevents wear and tear and ensures smooth operation. Regularly lubricate the lead screws, rods, and bearings to keep them moving smoothly. Use a quality lubricant specifically designed for 3D printers or mechanics. Apply the lubricant sparingly to avoid attracting dust and debris. Move the printer’s components back and forth after lubrication to distribute the lubricant evenly. Lubrication will minimize friction and reduce wear. When you lubricate moving parts, your printer will be much more efficient. Make sure to do this regularly, to prevent any damage or wear.

Upgrading Your Tarantula 3D Printer

Upgrading your Tarantula 3D printer can significantly enhance its capabilities and print quality (image tarantula-3d-printer-upgrades.webp). There is a vast range of upgrades you can do to improve your 3D printer. Consider the upgrades that will provide the most benefit based on your printing needs. Start with upgrades that are relatively easy to install. Make sure you are always following the instructions. Research the best options and consider the compatibility with your specific model. By upgrading your Tarantula, you can extend its lifespan and enhance its capabilities.

Upgrades

Various upgrades can enhance the performance of your Tarantula 3D printer. Some popular upgrades include replacing the stock hot end with an all-metal hot end for improved temperature resistance and filament compatibility. You can also consider upgrading the bed surface to improve adhesion, such as using a magnetic bed or a glass bed. Upgrade the firmware to provide additional features and enhancements. Adding a direct-drive extruder can improve print quality and filament control. Replacing the stepper drivers with more advanced drivers can reduce noise and improve print quality. You may also consider installing an enclosure to maintain a stable temperature and reduce warping. Researching and selecting upgrades can lead to significant improvements in printing quality and reliability.

Why Upgrade

Upgrading your Tarantula 3D printer can provide several advantages. Upgrades can improve print quality. Enhancements like better hot ends and improved bed surfaces will result in cleaner, more detailed prints. Moreover, upgrades enhance your printer’s reliability. Upgrading components will reduce potential breakdowns and ensure long-term performance. Upgrading your printer also offers increased filament compatibility. Some upgrades allow you to print with a broader range of materials. If you want to improve the print quality and reliability, think about some upgrades. Upgrades will give you enhanced printing performance and a better printing experience.