What is a Tarantula Helmet

A tarantula helmet, beyond its intriguing name, represents a cutting-edge approach to personal protective equipment. It’s designed with both aesthetics and functionality in mind, often incorporating advanced materials and engineering to provide superior protection. The term “tarantula” in this context could refer to the helmet’s design, inspired by the arachnid’s robust exoskeleton, or the overall focus on strength and resilience. These helmets are engineered to withstand impacts, abrasions, and various environmental hazards, making them suitable for a range of applications where head protection is paramount. The evolution of the tarantula helmet involves constant innovation, with manufacturers striving to improve protection levels, reduce weight, and enhance user comfort. This commitment to progress ensures that these helmets remain at the forefront of safety technology, offering reliable defense in demanding environments.

Tarantula Helmet Design and Materials

The design of a tarantula helmet is a complex undertaking, requiring careful consideration of form, function, and material selection. The external shell is crucial; it acts as the first line of defense against impacts, usually constructed from durable materials like high-strength polymers, reinforced composites, or specialized metals. Internal components, such as the liner, play a vital role in absorbing and dissipating impact energy, reducing the risk of injury to the wearer. Ventilation systems are integrated to regulate airflow, keeping the user cool and comfortable. Ergonomic considerations also shape the design, with features like adjustable straps and padding ensuring a secure and comfortable fit. The materials used significantly impact the helmet’s performance characteristics. The ideal combination of strength, weight, and flexibility is achieved through selecting appropriate materials, leading to various models each engineered for specific protection needs.

Materials Used in Tarantula Helmets

The materials used in tarantula helmets are selected to maximize protection, durability, and comfort. High-strength polymers like polycarbonate and ABS (Acrylonitrile Butadiene Styrene) are common for the outer shell, providing excellent impact resistance and lightweight properties. Advanced composites, such as fiberglass, carbon fiber, or Kevlar, enhance the helmet’s strength-to-weight ratio, making them ideal for applications where both protection and mobility are essential. The inner liners often utilize expanded polystyrene (EPS) or expanded polypropylene (EPP) foam, which effectively absorb and dissipate impact energy. Additional materials like padding, typically made of soft, moisture-wicking fabrics, are incorporated to enhance comfort and fit. Visors may employ polycarbonate or other impact-resistant materials to protect the wearer’s face. Each material is selected to contribute to the helmet’s overall effectiveness in safeguarding the user from a wide range of potential hazards.

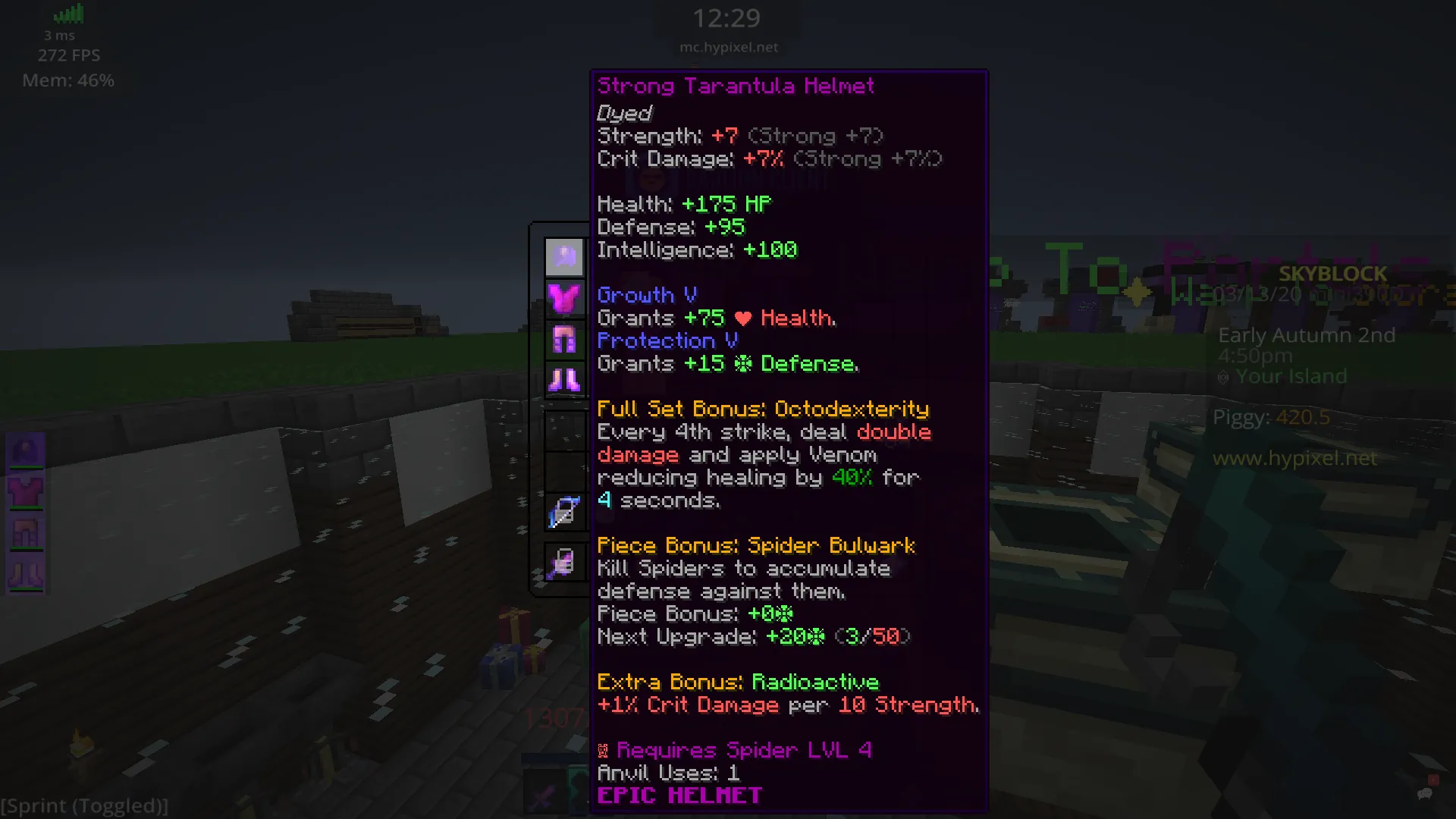

The Importance of Armor Strength

Armor strength is a critical attribute of any tarantula helmet, representing its capacity to withstand external forces without compromising the wearer’s safety. The strength of the armor directly determines the helmet’s ability to resist impacts, punctures, and abrasions, thus protecting the head from potential injuries. Strong armor can also help to reduce the likelihood of concussions or traumatic brain injuries by absorbing and distributing the impact energy more effectively. This is achieved through robust construction, employing materials and designs that enhance impact resistance. Helmets with superior armor strength offer better overall protection, making them an essential piece of equipment in hazardous environments. The significance of armor strength extends to the helmet’s durability and lifespan; stronger materials are more resistant to wear and tear, ensuring the helmet remains reliable over time. Therefore, assessing and prioritizing armor strength is crucial when choosing a tarantula helmet.

Armor Thickness and Protection Level

Armor thickness is directly related to the helmet’s overall protection level. Generally, thicker armor provides greater resistance to impacts and other hazards, as it can absorb and distribute more energy. However, increasing the thickness can also increase the weight of the helmet, potentially affecting the wearer’s comfort and mobility. The appropriate armor thickness is determined by the intended use of the helmet and the level of protection required. For example, helmets designed for high-impact activities may have thicker armor than those used for lower-risk environments. The protection level is often measured using industry-standard tests that assess the helmet’s ability to withstand specific forces. Certification standards dictate minimum performance criteria, ensuring that helmets meet a certain level of protection. The balance between armor thickness, weight, and protection level is critical in designing an effective and comfortable tarantula helmet.

Factors Affecting Armor Strength

Several factors influence the strength of tarantula helmet armor. The primary factor is the materials used; high-strength polymers, composites, and specialized metals inherently offer greater resistance to impacts and abrasions. The design and construction of the helmet play a significant role, with features like reinforcement ribs, multi-layer construction, and energy-absorbing liners enhancing overall protection. Manufacturing processes such as molding techniques and quality control measures also affect armor strength. Proper heat treatment or curing processes for materials ensure optimal performance. Environmental conditions, such as exposure to UV light or extreme temperatures, can degrade certain materials over time, impacting their strength. Maintenance practices, including regular inspections and proper storage, also play a vital role in preserving the armor’s integrity and ensuring its effectiveness. Regular inspections help identify any wear and tear that might affect armor strength.

Weight of the Helmet

The weight of a tarantula helmet is a crucial factor that impacts the wearer’s comfort, mobility, and overall experience. While heavier helmets may offer greater protection due to thicker armor and robust materials, they can cause fatigue and strain, particularly during prolonged use. Lighter helmets are generally preferred for tasks requiring agility and ease of movement. The helmet’s weight is influenced by the materials used, the design, and the addition of any integrated features, such as visors or communication systems. Manufacturers constantly strive to balance protection and weight, employing advanced materials and innovative designs to minimize the helmet’s mass without compromising safety. The weight of the helmet should be carefully considered based on the intended application and the user’s needs. A well-designed helmet will distribute weight evenly, reducing strain and enhancing overall comfort.

Impact Resistance

Impact resistance is a core characteristic of a tarantula helmet, representing its ability to withstand and absorb the energy from impacts. This crucial attribute minimizes the risk of head injuries by mitigating the force transmitted to the wearer’s skull. Impact resistance is achieved through the careful selection of materials, the design of the helmet’s structure, and the integration of energy-absorbing components. The outer shell provides initial protection by deflecting or distributing the impact force, while the inner liner absorbs and dissipates the remaining energy. Testing standards and certifications rigorously evaluate the helmet’s impact resistance, ensuring that it meets specific safety requirements. Helmets are subjected to controlled impacts, and their performance is measured to ensure they provide an adequate level of protection. High impact resistance is especially crucial in environments where the risk of head injury is high. This helps ensure the user’s safety, even under severe conditions.

How Tarantula Helmet Armor Works

Tarantula helmet armor works through a multi-layered approach to protect the wearer’s head. The outer shell acts as the primary line of defense, designed to resist penetration and distribute impact forces over a wider area. This shell is typically constructed from durable materials, such as polycarbonate, ABS, or composite materials. The inner layers, often composed of EPS or EPP foam, absorb and dissipate the impact energy. The foam compresses upon impact, significantly reducing the force transmitted to the wearer’s head. Additionally, features like suspension systems and padding enhance the helmet’s fit and comfort, further contributing to its protective capabilities. The armor’s effectiveness depends on its ability to withstand the force of impact without cracking or breaking, and to prevent any sharp objects from penetrating the shell. The combination of these features, along with proper fit and maintenance, ensures the helmet’s ability to protect the wearer in various hazardous situations.

The Role of the Helmet’s Structure

The structural design of the tarantula helmet plays a critical role in its ability to provide protection. The helmet’s shape, construction, and the arrangement of its components influence how it distributes and absorbs impact energy. A well-designed helmet will have a robust outer shell, often incorporating design features like ribs or ridges to increase strength and reduce the likelihood of fracture. The internal structure includes the suspension system, which creates a space between the head and the outer shell, further cushioning the impact. The placement of the helmet’s components, such as the liner and padding, is crucial for maximizing energy absorption. The overall structure should be stable, providing uniform protection across the head, and it should also incorporate features for ventilation to prevent overheating. Careful consideration of the helmet’s structural design ensures its overall effectiveness in safeguarding the wearer’s head.

Benefits of Strong Tarantula Helmet Armor

The benefits of strong tarantula helmet armor are numerous and directly translate to enhanced safety and protection. Strong armor increases the helmet’s ability to withstand impacts, reduces the risk of serious head injuries, and enhances the wearer’s overall safety in hazardous environments. This protection can be critical in preventing concussions, skull fractures, and traumatic brain injuries, which can have lasting effects. In addition to safety, robust armor offers increased durability and longevity, reducing the need for frequent replacements. Stronger helmets often provide better resistance to abrasion and environmental factors. These helmets instill confidence in the wearer, knowing that they are protected by a reliable piece of equipment designed to withstand demanding conditions. The advantages of strong armor extend to improved performance, as the wearer can focus on their task without worrying about their safety.

Enhanced Safety and Protection

Enhanced safety and protection are the primary benefits of strong tarantula helmet armor. The helmet’s design, materials, and construction work together to reduce the risk of head injuries. A strong helmet absorbs and dissipates impact energy, minimizing the force transmitted to the wearer’s head. This reduces the likelihood of concussions, skull fractures, and other traumatic injuries. Stronger armor also provides better protection against penetration from sharp objects and offers greater resistance to abrasion. Certification standards and testing methods are used to ensure that the helmet meets specific safety requirements. The goal of superior safety and protection is achieved through a multi-faceted approach that prioritizes robust design, durable materials, and rigorous testing. The wearer can perform their tasks confidently, knowing they are adequately protected against potential hazards.

Durability and Longevity

Durability and longevity are important aspects of strong tarantula helmet armor. Helmets built with robust materials and superior construction can withstand wear and tear, extending their lifespan. Stronger armor is less susceptible to damage from impacts, abrasions, and environmental factors. The helmet’s ability to maintain its protective properties over time is crucial for ensuring consistent safety. Regular maintenance, including inspections and cleaning, contributes to the helmet’s durability. A durable helmet requires fewer replacements, reducing both the cost and the environmental impact. Durability is often associated with the quality of the materials used. A longer lifespan provides a better return on investment. A strong and durable tarantula helmet is a practical and cost-effective investment in safety, providing long-lasting protection for the wearer.

Types of Tarantula Helmet Armor

Tarantula helmet armor comes in various types, each designed to meet specific protection needs and offer unique advantages. Different types of armor utilize a range of materials and construction techniques to provide varying levels of protection. The primary types of armor include metal-based, composite, and ceramic armor, each with distinct properties that determine their suitability for different applications. These various types of armor demonstrate manufacturers’ commitment to provide the most suitable options for different hazards. Understanding the features and benefits of each type allows users to select a helmet that best suits their requirements.

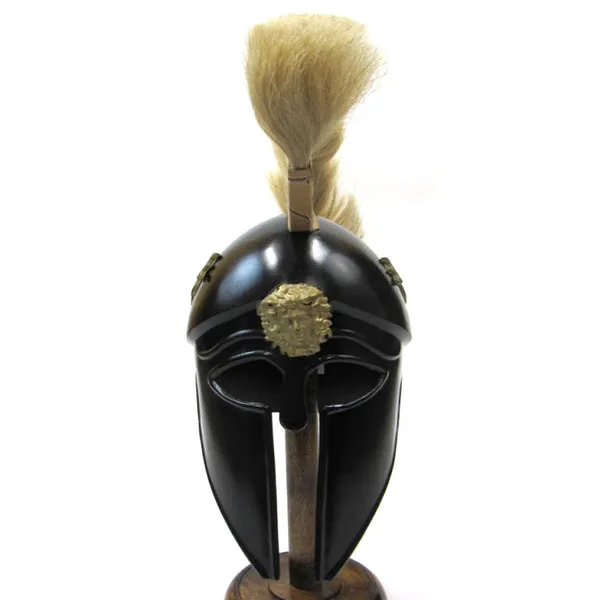

Metal-Based Armor

Metal-based armor for tarantula helmets typically utilizes materials like steel, aluminum alloys, or titanium, chosen for their high strength and resistance to impact. Steel offers excellent strength and durability, making it suitable for heavy-duty applications. Aluminum alloys provide a balance of strength and lightweight properties. Titanium is known for its exceptional strength-to-weight ratio, making it ideal for situations where weight is a critical factor. Metal armor is constructed with varying thicknesses and designs to provide optimal protection against different types of threats. Metal armor can be treated with coatings or finishes to enhance its corrosion resistance and wear resistance. Though metal-based armor is very protective, it can be heavier than other types of armor. This makes it suitable for environments where superior protection is required and weight is not the primary concern.

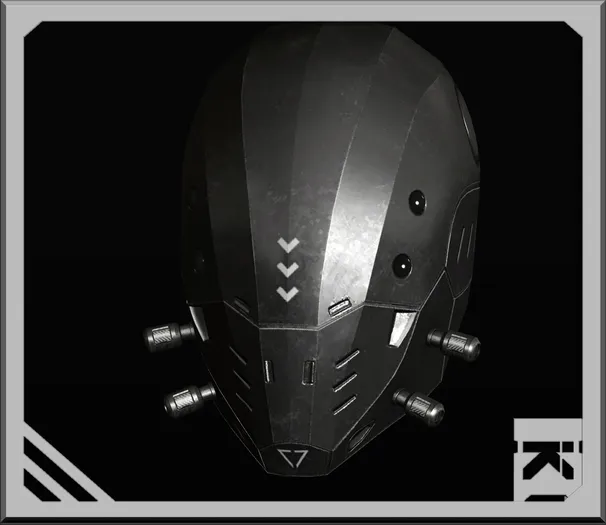

Composite Armor

Composite armor uses a combination of materials, such as fiberglass, carbon fiber, or Kevlar, to provide a balance of strength, weight, and flexibility. Fiberglass is a common choice for its high strength-to-weight ratio and relatively low cost. Carbon fiber offers exceptional strength and lightweight properties, making it ideal for applications where performance is a priority. Kevlar is known for its high tensile strength and resistance to penetration, making it valuable for ballistic protection. Composite armor is constructed by layering the different materials, often with a resin matrix to bind them together. This construction allows the armor to absorb and dissipate impact energy more effectively. Composite materials allow manufacturers to tailor the helmet’s properties to specific needs. Composite armor is often lighter than metal-based armor, making it suitable for applications where mobility and comfort are critical.

Ceramic Armor

Ceramic armor utilizes materials like alumina (aluminum oxide) or boron carbide, which are chosen for their exceptional hardness and ability to defeat projectiles. Ceramic armor is designed to shatter or erode the incoming projectile, absorbing its energy and preventing penetration. Ceramic armor is often used in conjunction with other materials, such as composites, to create a multi-layered system. The ceramic layer faces the threat, while the composite layer absorbs the remaining impact energy. The main advantage of ceramic armor is its ability to stop high-velocity projectiles. It’s often used in ballistic helmets and other types of protective gear. However, ceramic armor can be more susceptible to cracking or damage from multiple impacts. This design requires a balance between protection and the helmet’s overall weight and durability. Ceramic armor provides a high level of protection against specific threats.

Maintenance and Care for Tarantula Helmet Armor

Proper maintenance and care are essential for preserving the performance and extending the lifespan of tarantula helmet armor. Regular cleaning, inspection, and storage practices contribute to the helmet’s effectiveness and help identify any potential issues. Following the manufacturer’s instructions for cleaning, maintenance, and storage is crucial to ensure proper care. This includes the use of appropriate cleaning agents, and following the correct storage procedures. Consistent care prevents the degradation of materials and ensures that the helmet provides the necessary protection. Proper maintenance helps avoid premature damage or failure. A well-maintained helmet is more likely to perform effectively, providing the required protection. Careful maintenance and care significantly extend the helmet’s useful life.

Cleaning and Inspection

Regular cleaning and inspection are essential maintenance steps for tarantula helmet armor. The helmet should be cleaned after each use, following the manufacturer’s guidelines. Use a mild soap and water solution to remove dirt, debris, and contaminants that may compromise the armor’s integrity. Avoid abrasive cleaners or harsh chemicals that can damage the materials. Inspect the helmet regularly for signs of damage, such as cracks, dents, or abrasions. Check the straps, padding, and other components for wear and tear. Look for any loose connections or damage that could compromise the helmet’s ability to provide protection. Any damage should be addressed promptly. Cleaning removes contaminants, while inspections detect potential issues early on. Performing these maintenance activities correctly is crucial for keeping the helmet safe and in good working order.

Storage and Handling

Proper storage and handling are essential for preserving the integrity and extending the lifespan of tarantula helmet armor. Store the helmet in a cool, dry place away from direct sunlight, extreme temperatures, and chemicals that could damage the materials. Avoid dropping the helmet or subjecting it to unnecessary impacts, as this can cause damage that may compromise its protective capabilities. When storing the helmet, ensure that it is properly supported to prevent deformation or damage. The helmet should be stored where it is easily accessible when needed. Following storage procedures and guidelines can help maintain the helmet’s performance. Handle the helmet with care to prevent damage. Correct storage and handling ensure that the helmet is ready and effective whenever it is needed. Careful handling and storage prolongs the helmet’s useful life.

Where to Buy Tarantula Helmet Armor

Tarantula helmet armor can be purchased from various sources, including specialized safety equipment retailers, online marketplaces, and directly from manufacturers. When choosing a supplier, consider factors such as product selection, pricing, reputation, and customer service. Specialty retailers often offer a wide range of helmets and related accessories, along with expert advice. Online marketplaces provide a convenient platform for comparing different models. Purchasing directly from the manufacturer is a way to ensure authenticity and receive the most up-to-date information. Researching reviews and checking certifications can help ensure that the helmet meets the required safety standards. Look for reputable suppliers that offer a warranty on their products. Consider the specific needs of the application and consult with experts to make the best selection. Selecting the right vendor ensures the purchase of a quality product. Doing so will guarantee that you receive genuine, effective, and safe tarantula helmet armor.