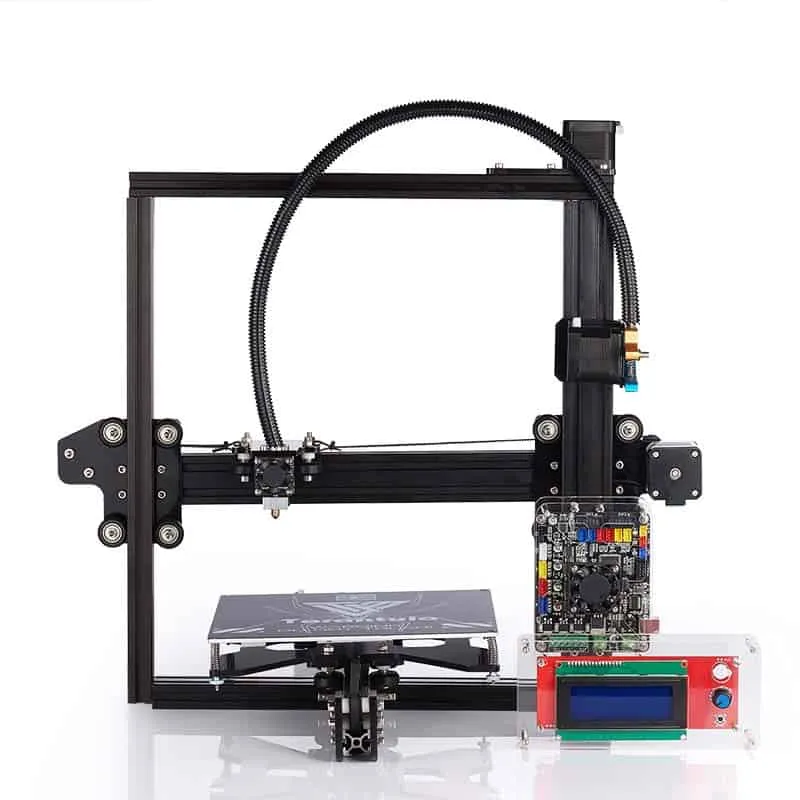

Tevo Tarantula Pro Assembly Overview

Assembling the Tevo Tarantula Pro can seem like a daunting task at first, but with the right approach and a clear understanding of the process, it can be an enjoyable and rewarding experience. This quick guide provides a step-by-step walkthrough to help you successfully assemble your 3D printer. We’ll cover everything from unboxing to your first successful print, addressing common pitfalls and offering valuable tips along the way. Remember to take your time, follow the instructions carefully, and don’t hesitate to seek help from online communities if you get stuck. Patience and attention to detail are key to a smooth assembly process and a fully functional 3D printer.

Tools and Materials Needed

Before you begin, gather all the necessary tools and materials. The Tevo Tarantula Pro typically comes with most of what you need, but it’s a good idea to have a few extra items on hand. You will need the provided tools (Allen wrenches, screwdrivers), a set of wire cutters, a multimeter (optional but recommended for troubleshooting), zip ties, and possibly some electrical tape. It’s also helpful to have a clean workspace and good lighting. Organize all of the parts as you unbox them to prevent confusion during the assembly process. Having everything readily available will save you time and frustration as you work through each step.

Unboxing and Preparation

Carefully unpack all the components of your Tevo Tarantula Pro, making sure to keep all the screws, nuts, and bolts organized. The printer usually comes in several packages with different parts. Check the packing list to ensure all components are present. Lay out the parts on your workspace and take inventory. This is also a good time to familiarize yourself with the different parts and their functions. Locate the instruction manual, which will be your primary guide throughout the assembly process. Don’t be afraid to consult online resources like YouTube videos if the manual isn’t entirely clear. Unboxing is the first step to your 3D printing journey. (Image: tevo-tarantula-pro-unboxing.webp)

Step-by-Step Assembly Guide

Base and Frame Assembly

Start by assembling the base and frame of the printer. This usually involves attaching the vertical supports to the base using the appropriate screws and bolts. Ensure that the frame is square and sturdy. Tighten the screws securely, but avoid over-tightening, which could strip the threads. Refer to the manual for specific screw types and placement. The frame provides the structural integrity of the printer, so ensuring its stability is crucial for the quality of your prints. (Image: tevo-tarantula-pro-frame.webp)

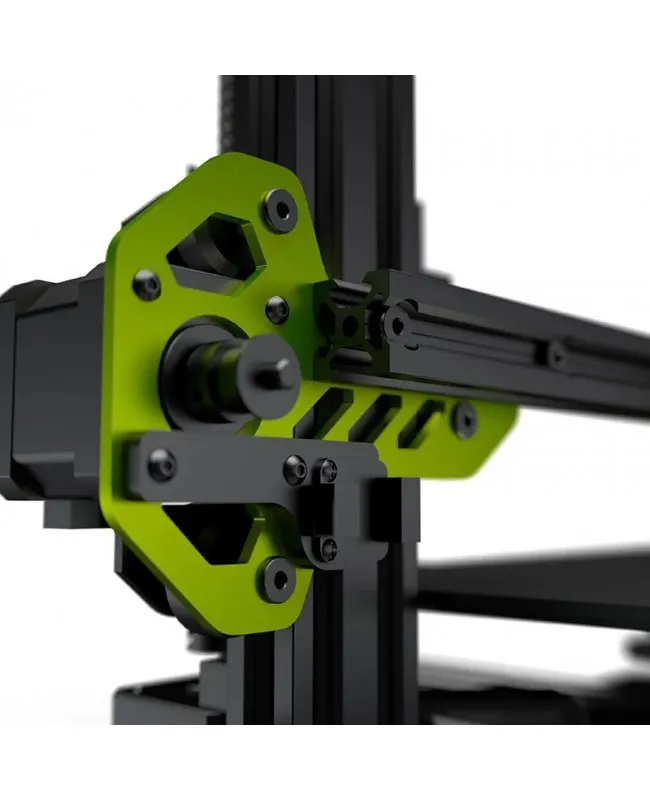

X-Axis and Y-Axis Assembly

Next, assemble the X-axis and Y-axis components. This involves attaching the moving parts (carriage, rods, belts) to the frame. Carefully follow the instructions for belt tensioning, as proper tension is critical for accurate movements. The X-axis carries the hotend, while the Y-axis moves the print bed. Make sure the axes move smoothly and without binding. Lubricating the rods with grease can help reduce friction and improve performance. Aligning these axes correctly will ensure accurate printing. Ensure that the belts are not too loose or too tight; a good starting point is to ensure they can be slightly deflected with your finger.

Z-Axis Assembly

The Z-axis controls the vertical movement of the print head. Assemble the Z-axis according to the manual, paying close attention to the alignment of the threaded rods and the motor mounts. Properly aligning the Z-axis is essential for layer adhesion and overall print quality. Ensure the Z-axis moves smoothly up and down without any wobbling. The Z-axis endstop switch needs to be positioned correctly to ensure that the nozzle doesn’t crash into the bed during initial setup. This is also where the Z-axis lead screws are installed and aligned.

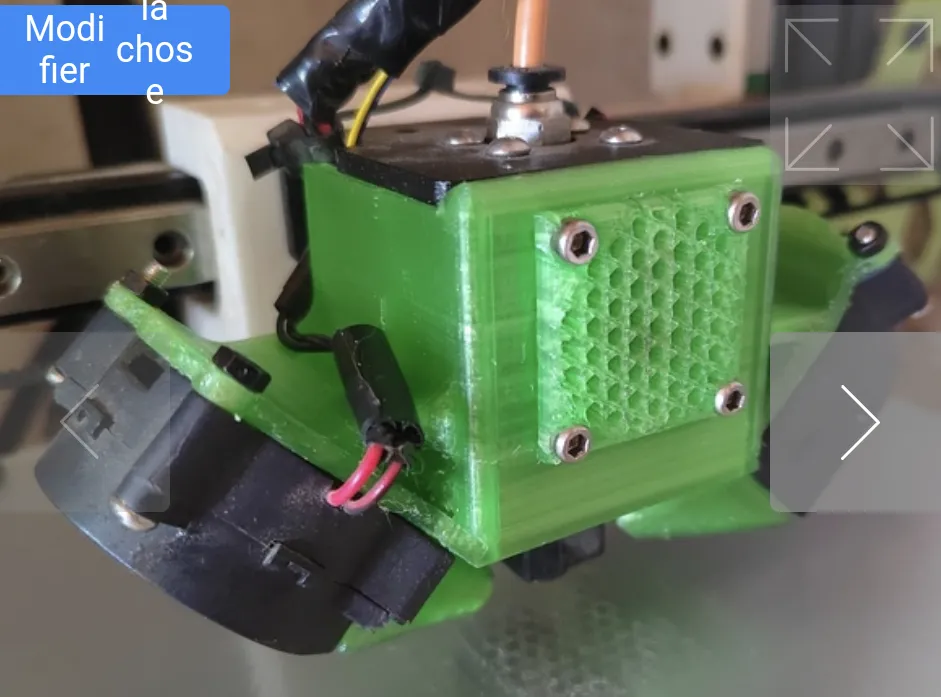

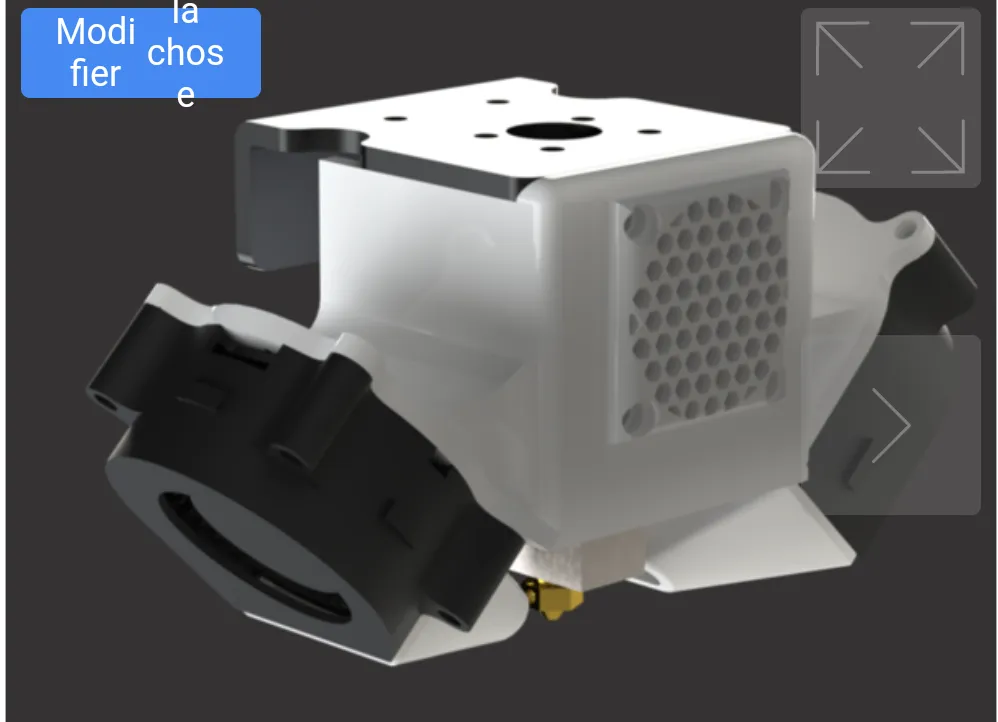

Hotend and Extruder Assembly

The hotend and extruder are critical components for melting and extruding the filament. Assemble the hotend (nozzle, heater block, heat sink) according to the instructions, and attach it to the X-axis carriage. The extruder motor and filament feed mechanism must be mounted securely. Ensure the hotend is properly insulated to maintain temperature stability. Double-check all connections and tighten screws carefully to prevent leaks or blockages. Make sure the thermistor and heater cartridge are securely installed. This is the area of the printer that will heat the filament and extrude it to build your 3D model. (Image: tevo-tarantula-pro-hotend.webp)

Electronics and Wiring

Wiring the electronics can be a complex part of the assembly. Carefully connect the motors, endstops, heater cartridges, and thermistors to the control board, following the wiring diagrams in the manual. Make sure all the connections are secure and properly insulated. Use zip ties to keep the wires neat and organized, minimizing the risk of them interfering with the moving parts. Double-check all connections before powering on the printer. Incorrect wiring can damage the printer or pose a safety hazard. This is often the part where beginners get stuck. (Image: tevo-tarantula-pro-electronics.webp)

Bed Leveling and Calibration

Proper bed leveling is essential for successful prints. The Tevo Tarantula Pro usually has manual bed leveling, using adjustment knobs to set the height of the print bed relative to the nozzle. Calibrate the bed by moving the nozzle to several points on the bed and adjusting the knobs until the nozzle is at the correct distance from the bed. Use a piece of paper to gauge the distance – the nozzle should lightly grip the paper. Also calibrate the X, Y, and Z axes for accurate movements. Fine-tuning these settings may take a few tries, but it will significantly improve your print quality. (Image: tevo-tarantula-pro-calibration.webp)

Software Setup and Firmware

Install the necessary software on your computer, including a slicer program (such as Cura or PrusaSlicer). Slicers convert your 3D models into G-code, which the printer uses to print. Download the firmware for your Tevo Tarantula Pro and upload it to the printer’s control board. Configure the slicer settings according to your printer’s specifications. This includes setting the bed size, nozzle size, and filament type. Experiment with different settings (temperature, print speed, layer height) to optimize your prints. Correctly configuring the software is essential for your first successful print.

Initial Print and Testing

Once the printer is assembled, leveled, and the software is set up, it’s time for your first print. Choose a simple test model (like a calibration cube or a small benchy) and load it into the slicer. Load filament into the extruder, preheat the nozzle, and start the print. Monitor the first few layers closely to ensure the filament is adhering properly to the bed. If necessary, adjust the bed leveling or nozzle height during the print. Take notes on what you see for future improvement. (Image: tevo-tarantula-pro-first-print.webp)

Troubleshooting Common Issues

Extruder Issues

Extruder problems can lead to inconsistent filament flow and poor print quality. Common issues include: filament not feeding, filament grinding, and under-extrusion. Check for clogs in the nozzle, adjust the extruder tension, and ensure the filament is feeding smoothly. The extruder motor may need to be calibrated in the firmware, ensuring it pushes the right amount of filament for each movement. If the extruder is clicking, it’s a sign of blockage, and you will have to unclog the nozzle, or increase the temperature.

Bed Adhesion Problems

Poor bed adhesion is a common challenge for 3D printing newbies. This issue causes the print to detach from the bed. You can address this by properly leveling the bed, cleaning the bed surface, and applying an adhesive (such as glue stick or hairspray). Adjust the bed temperature for the filament type and, if necessary, print with a brim or raft to increase the contact surface area. Ensure the nozzle is close enough to the bed, but not so close that it scratches it.

Nozzle Clogging

Nozzle clogging can disrupt the printing process, resulting in failed prints. The nozzle can become clogged due to various factors, including heat creep, degraded filament, or debris. Increase the nozzle temperature, perform a cold pull, or use a nozzle cleaning tool. Preventative measures include using high-quality filament, ensuring proper cooling of the heat sink, and occasionally cleaning the nozzle. Make sure to use a nozzle that is compatible with the Tevo Tarantula Pro. Replace the nozzle if necessary, after which you may need to re-calibrate the bed.

Firmware and Software Conflicts

Firmware and software issues can manifest as incorrect movements, temperature errors, or communication failures. Make sure you’re using the correct firmware version for your printer. Double-check your slicer settings to ensure they are compatible with your printer and filament type. Try reinstalling the firmware and the slicer software. Update the printer drivers and ensure your computer’s operating system is compatible. Check for any potential communication issues between the computer and the printer.

Final Tips and Tricks

Maintenance and Cleaning

Regular maintenance is crucial for keeping your Tevo Tarantula Pro running smoothly. Clean the print bed after each print. Periodically lubricate the rods and belts. Tighten any loose screws. Clean the nozzle regularly, and check the wiring for wear and tear. Store filament properly to prevent moisture absorption. Regularly inspect and clean the printer to ensure a long lifespan and optimal performance.

Upgrades and Modifications

Once you’re comfortable with the basics, you can consider upgrades and modifications. Popular upgrades include a glass bed, improved hotend, auto-bed leveling, and silent stepper drivers. These upgrades can enhance print quality, ease of use, and reduce noise. However, upgrade judiciously, and always research the compatibility and installation process. Explore online communities for ideas and tutorials on these modifications. This will help extend the printer’s capabilities.