Understanding the Tevo Tarantula Pro

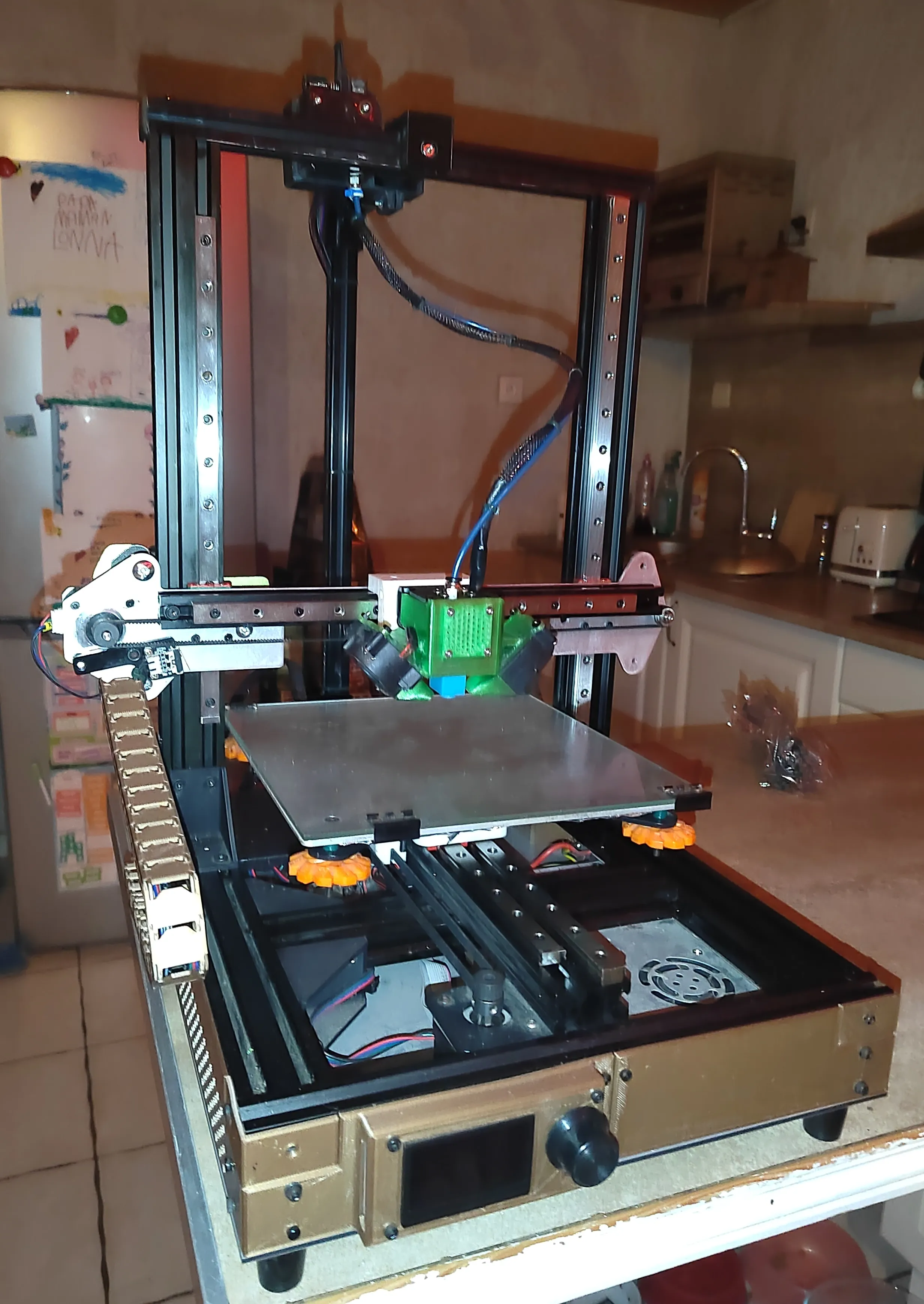

The Tevo Tarantula Pro is a popular 3D printer known for its affordability and ease of use, making it a great choice for both beginners and experienced makers. It offers a decent build volume, allowing for the creation of various sized prints. The printer’s open-frame design gives easy access to the print bed and components. However, to get the best results from the Tevo Tarantula Pro, it’s crucial to optimize your Cura profile, which dictates how your printer interprets and executes 3D models. Understanding the printer’s capabilities and limitations is the first step in achieving high-quality prints.

Key Features of the Tevo Tarantula Pro

The Tevo Tarantula Pro boasts several features that make it a favorite among 3D printing enthusiasts. These include a heated bed, which is essential for printing materials like ABS and PETG, preventing warping. It usually includes a direct drive extruder, improving print quality, especially with flexible filaments. The printer often comes with a built-in LCD screen and SD card reader, which provides an easy way to manage print jobs. Also, its sturdy construction contributes to its overall reliability. Knowing these features helps in tailoring your Cura profile for optimal performance.

Importance of a Good Cura Profile

A well-configured Cura profile is the key to unlocking the full potential of your Tevo Tarantula Pro. A good profile ensures that your printer operates efficiently, producing high-quality prints with minimal errors. It affects every aspect of the print process, from the initial adhesion to the final surface finish. Without a properly tuned profile, you might experience issues like poor layer adhesion, warping, stringing, and failed prints. Taking the time to create and refine your Cura profile is an investment in the quality and reliability of your 3D printing projects.

Why Cura is Essential for Tevo Tarantula Pro

Cura is a user-friendly and powerful slicer software that converts 3D models into instructions that your Tevo Tarantula Pro can understand. Its intuitive interface makes it easy to adjust settings, preview print jobs, and manage your 3D printing workflow. Cura is widely used and well-supported by a large community, offering numerous guides, profiles, and resources to help you optimize your printing experience. Using Cura allows you to precisely control every aspect of the printing process, leading to consistently high-quality results. Its compatibility and extensive features make it the go-to choice for most Tevo Tarantula Pro users.

Setting Up Cura for Your Tevo Tarantula Pro

Setting up Cura for your Tevo Tarantula Pro starts with installing the software and adding your printer. Once installed, you’ll need to configure the printer settings to match your Tevo Tarantula Pro’s specifications. This includes the print bed size, nozzle diameter, and any other relevant hardware details. Cura has a built-in printer selection, but if not available, you can manually add your printer. Correctly configuring the printer settings provides a solid foundation for accurate and reliable prints, setting the stage for optimizing your Cura profile. Ensure you select the correct printer model in Cura, and calibrate your printer’s bed.

Printer Settings Configuration

The printer settings are the backbone of your Cura profile. These settings tell Cura about your printer’s physical properties and capabilities. Proper configuration here is essential. Enter your print bed dimensions, which are crucial for determining the build volume. Also, make sure you specify the correct nozzle diameter, as this will affect the print quality and speed. Other important settings include the type of hot end and any upgrades you might have added to your printer, such as a different extruder or a new heat bed. Correct settings will prevent many print errors and enhance the print quality.

Bed and Build Volume Settings

Accurate bed and build volume settings are critical for ensuring your prints fit within your printer’s physical boundaries. You need to accurately input the dimensions of your printer’s build plate to prevent the slicer from generating prints that are too large. Incorrect dimensions can lead to the printer trying to print outside of its physical limits, causing failures and potential damage. Also, ensure you configure the correct Z-offset to ensure that the nozzle starts at the correct distance from the bed, thus avoiding adhesion problems. Check the printer’s manual for dimensions and enter them correctly in Cura.

Extruder Settings Optimization

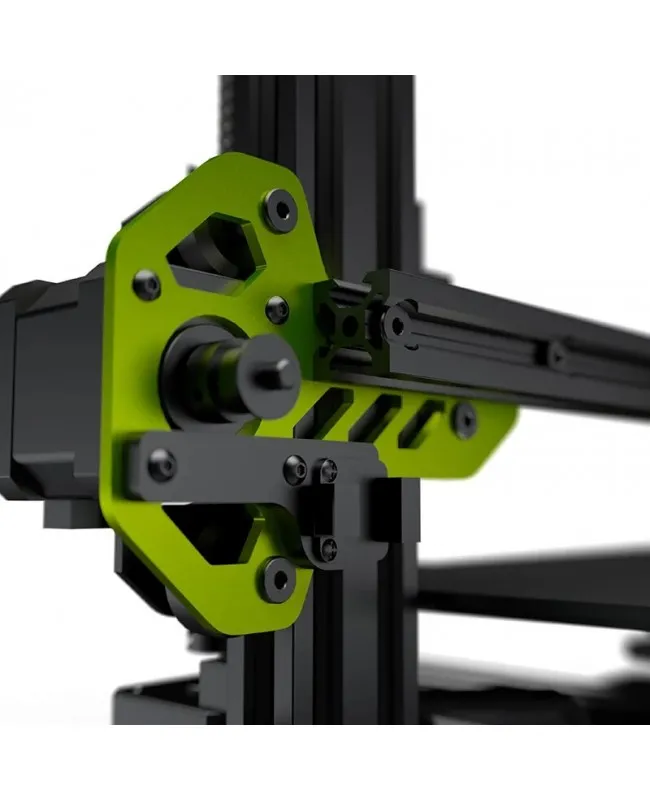

Extruder settings are essential for controlling how filament is fed through the nozzle. Properly calibrated extruder settings are vital for achieving consistent extrusion and preventing common problems such as under-extrusion and over-extrusion. Calibrating your extruder involves measuring and adjusting the steps per millimeter (e-steps) to ensure the printer extrudes the correct amount of filament. Check for any extruder upgrades like a direct drive system or a different type of extruder, as these require specific setting adjustments. Also, fine-tune the flow rate settings to get the right amount of filament during printing.

Nozzle and Filament Configuration

The nozzle size and filament type settings impact the printing resolution, speed, and material properties. The nozzle diameter affects the level of detail and the speed at which you can print. Smaller nozzles provide more detail, whereas larger nozzles enable faster printing. Selecting the right filament type is also very important. Choose the right filament in Cura, considering the printing temperature, bed temperature, and other material-specific settings. Different filaments, such as PLA, ABS, PETG, and TPU, each have unique characteristics that require tailored settings. Choosing the correct settings will lead to optimal print quality.

Print Speed and Temperature Settings

Print speed and temperature are critical factors in determining the quality and success of your prints. The print speed affects how quickly your print is made, while the temperature dictates how the filament melts and fuses together. The optimal print speed depends on the material used, the complexity of the model, and the desired print quality. Setting the correct temperature is essential for getting good layer adhesion and preventing issues like warping. Usually, you will choose temperatures based on the filament type and its specifications. Experiment with different speeds and temperatures to find what suits your needs.

Optimizing Print Speed

Finding the right print speed is a balance between speed and quality. Printing too fast can lead to defects like layer shifting, poor surface finish, and incomplete extrusion. Start with a slower speed and gradually increase it until you notice a decline in quality. The optimal print speed also varies depending on the filament type and the complexity of the model. For detailed models, you might need to reduce the print speed to maintain accuracy and quality. Monitor your prints closely as you adjust the speed settings, and adjust accordingly. Refer to the filament specifications to see the suggested printing speeds.

Choosing the Right Temperature

The correct temperature is crucial for ensuring the filament melts and bonds together properly. Too low a temperature results in under-extrusion and poor layer adhesion, while too high a temperature leads to stringing and oozing. Check the filament manufacturer’s recommendations for the ideal printing temperature range. Conduct test prints to find the temperature range that produces the best results for your specific filament. Consider the environment, as room temperature can affect the printing. A good starting point is to set your print head temperature in the middle of the suggested range and adjust from there. It will take some tests before finding the right temperature.

Retraction Settings for Better Prints

Retraction settings are a critical element for minimizing stringing and oozing, which is caused by filament leaking from the nozzle during travel moves. Proper retraction pulls the filament back into the nozzle, preventing it from dripping and creating unwanted strings on your print. Adjusting the retraction settings requires balancing retraction distance and retraction speed. Too much retraction can cause clogs, while too little leads to stringing. The right settings depend on your filament type, nozzle size, and printer setup. Experiment with your retraction settings until you obtain the desired print quality.

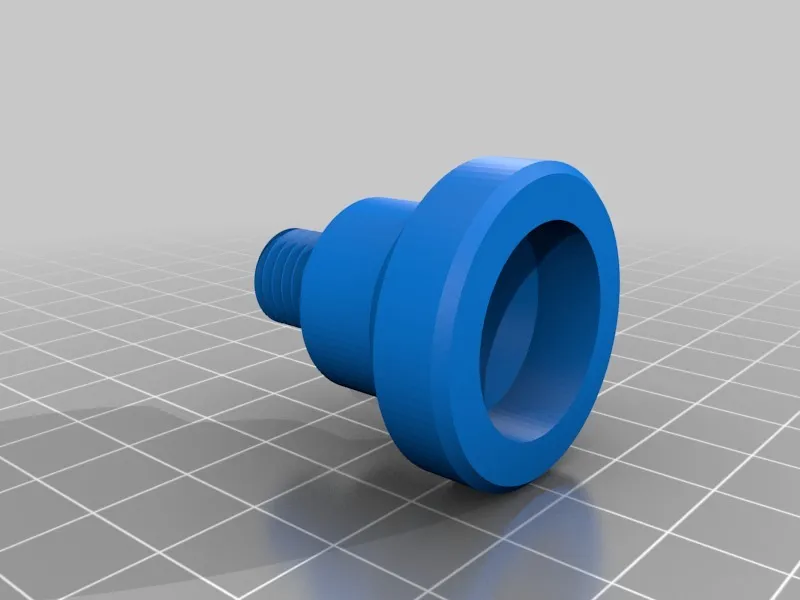

Understanding Retraction

Retraction is the process by which the 3D printer pulls the filament back from the nozzle when the print head moves to a new location. This action prevents the filament from oozing out and creating stringing or blobs on the print. The effectiveness of retraction depends on factors like the filament type, nozzle temperature, and the type of extruder you have. Direct drive extruders tend to require shorter retraction distances compared to Bowden tube setups. Understanding retraction helps you fine-tune your Cura profile for optimal performance. Consider filament properties to ensure optimal settings.

Configuring Retraction Settings

Configuring retraction settings in Cura involves adjusting the retraction distance and speed. Retraction distance controls how much filament is pulled back, and retraction speed determines how quickly this happens. For many filaments, a good starting point is a retraction distance of 2-6 mm and a speed of 25-45 mm/s. Fine-tune these settings through test prints. If you notice stringing, try increasing the retraction distance. If you experience clogs, reduce it. Adjusting the retraction speed can help. Remember to save your settings after each adjustment.

Cooling Settings and Their Impact

Cooling settings directly influence the quality and accuracy of your prints. Proper cooling helps solidify each layer before the next one is added, preventing warping, sagging, and poor surface finish. The cooling fan directs airflow onto the printed parts, assisting in the rapid cooling of the extruded plastic. Adjusting the fan speed, the direction of airflow, and the minimum layer time settings can significantly improve the print quality. Using the appropriate cooling strategy is especially important when printing overhangs and bridges.

Fan Speed and Cooling Strategies

Fan speed and cooling strategies are key to managing the cooling process. The cooling fan speed affects how quickly the printed layers cool. Start with a moderate fan speed and adjust based on the filament being used. PLA, for instance, benefits from high fan speeds, while ABS generally requires lower speeds. Consider using adaptive cooling, which automatically adjusts fan speed based on print conditions. Also, ensure your cooling fan is properly positioned to direct airflow to the print, not away from it. For overhangs, reduce the print speed to improve cooling.

Layer Height and Quality

Layer height plays a crucial role in print quality, and it directly impacts the resolution and the time it takes to complete the print. A smaller layer height results in smoother surfaces and finer details. However, it also increases the printing time. A larger layer height allows for faster printing, but it can make the layers more noticeable. Selecting the ideal layer height involves balancing quality, speed, and the specific requirements of your print. Knowing the ideal layer height helps you to optimize your prints to get the best possible outcome.

Determining the Right Layer Height

Determining the right layer height depends on your nozzle size, the type of filament, and the details of your 3D model. A general rule is to keep the layer height between 25% and 75% of the nozzle diameter. For instance, a 0.4mm nozzle works best with layer heights between 0.1mm and 0.3mm. When choosing a layer height, consider how the print will be used and what features are the most important. If you need high detail, choose a small layer height; if speed is more important, you can choose a larger layer height. Experiment with the settings to see what works best for your projects. Test different models for the best outcome.

Infill Settings for Strength and Speed

Infill settings determine the internal structure of your 3D print, impacting both its strength and printing time. The infill percentage controls the density of the internal structure. A higher infill percentage results in a stronger part but takes longer to print. The infill pattern, such as rectilinear, gyroid, or honeycomb, affects the strength and the appearance of the printed part. Choosing the right infill settings is essential for achieving the desired balance between part strength, print time, and material usage. The infill settings will significantly impact the print result.

Choosing the Right Infill Percentage

The ideal infill percentage depends on the function of your printed part. For parts that need to withstand heavy loads or have critical structural roles, you might use an infill percentage of 50% or higher. For decorative or non-functional parts, a lower infill percentage (10-20%) might be sufficient. A good starting point for many prints is around 20%. You should adjust the infill percentage based on the mechanical requirements of your project. Infill settings will significantly impact the print result, so adjust it based on the project requirements.

Support Structures Configuration

Support structures are essential for printing models with overhangs, bridges, or complex geometries. They provide a base for the printer to build on, preventing parts of the model from drooping or collapsing during printing. Configuring support structures in Cura allows you to specify where and how supports are generated, as well as the material used. Understanding the options for support structures helps ensure successful prints with intricate designs. Incorrect supports can ruin prints, so you need to ensure the correct settings are set.

When to Use Support Structures

Support structures are needed when printing overhangs that exceed a certain angle (usually 45 degrees). They are also necessary for bridging, which is printing across gaps, and for complex geometries that would otherwise collapse. You can use Cura to automatically generate supports, or you can manually place them. When deciding whether to use supports, consider the design, the desired quality, and the ease of removing supports from the finished print. The best settings depend on the specific design.

Advanced Cura Profile Tweaks

Beyond the basic settings, several advanced tweaks can further optimize your Cura profile. These settings let you fine-tune your prints. The settings will help ensure you produce the best possible print results. Consider experimenting with coasting, which reduces stringing by stopping the extrusion before the print head moves. Optimize the print order. This will prevent print defects. These advanced tweaks allow you to fine-tune the printing process.

Fine Tuning for Specific Materials

Different 3D printing materials require different settings for optimal results. PLA is generally easy to print with but requires a lower temperature and good cooling. ABS requires higher temperatures and a heated bed to prevent warping. PETG offers a good balance of properties and is suitable for various applications. TPU (thermoplastic polyurethane) is flexible and requires slower print speeds and specific retraction settings. Refer to material data sheets and experiment with settings to dial in your prints. Use the proper settings based on the material being used.

Troubleshooting Common Printing Issues

Even with a well-configured Cura profile, you may encounter printing issues. These issues are frequently related to specific settings. Common problems include bed adhesion issues, warping, stringing, under-extrusion, and layer shifting. Diagnosing and solving these problems involves a systematic approach. Start by checking the bed leveling and cleaning the print surface. Adjust the first-layer settings, which are crucial for bed adhesion. Review your retraction settings to fix stringing. Increase the temperature or adjust your extruder settings to solve under-extrusion. Check for loose belts or other mechanical problems. By knowing what to look for, you can quickly find the root cause.

Common Print Defects and Solutions

Several common print defects can be easily addressed with adjustments to your Cura profile. Warping is when the print curves upwards off the print bed, which is often caused by insufficient bed adhesion or too low a bed temperature. Stringing results in thin strands of filament connecting parts of the print, generally caused by incorrect retraction settings or excessive temperatures. Under-extrusion is when the layers are not solid or have gaps, which can be caused by a clogged nozzle, incorrect extruder calibration, or too low a temperature. Layer shifting is when the layers of the print are misaligned, which may be due to loose belts or mechanical issues. Recognizing these issues helps you find the root cause.

Maintaining Your Cura Profile

Maintaining your Cura profile is important for consistency and long-term performance. As you try new filaments or tweak your settings, it’s important to regularly save and update your profiles. Create different profiles for various filament types and print requirements, so you don’t have to constantly reconfigure settings. Keep a log of your changes, including the settings you adjusted and the outcomes. This will help you identify settings that work best. Regularly back up your Cura profiles to prevent losing your configurations. This will save you time in the future.

Regular Profile Updates

Keep your Cura profiles updated as you gain experience and refine your printing skills. Regularly review and refine the settings to suit your changing needs. You might discover new filaments or printing techniques. With each new discovery, revisit your profiles. Also, make sure your Cura software is updated to the latest version, as updates often include improvements and bug fixes. A well-maintained Cura profile will help you achieve consistently high-quality prints with your Tevo Tarantula Pro, ensuring that your prints come out great every time. This practice will ensure that you always get the most out of your printer.