Unlocking Tevo Tarantula Z-Rod Potential

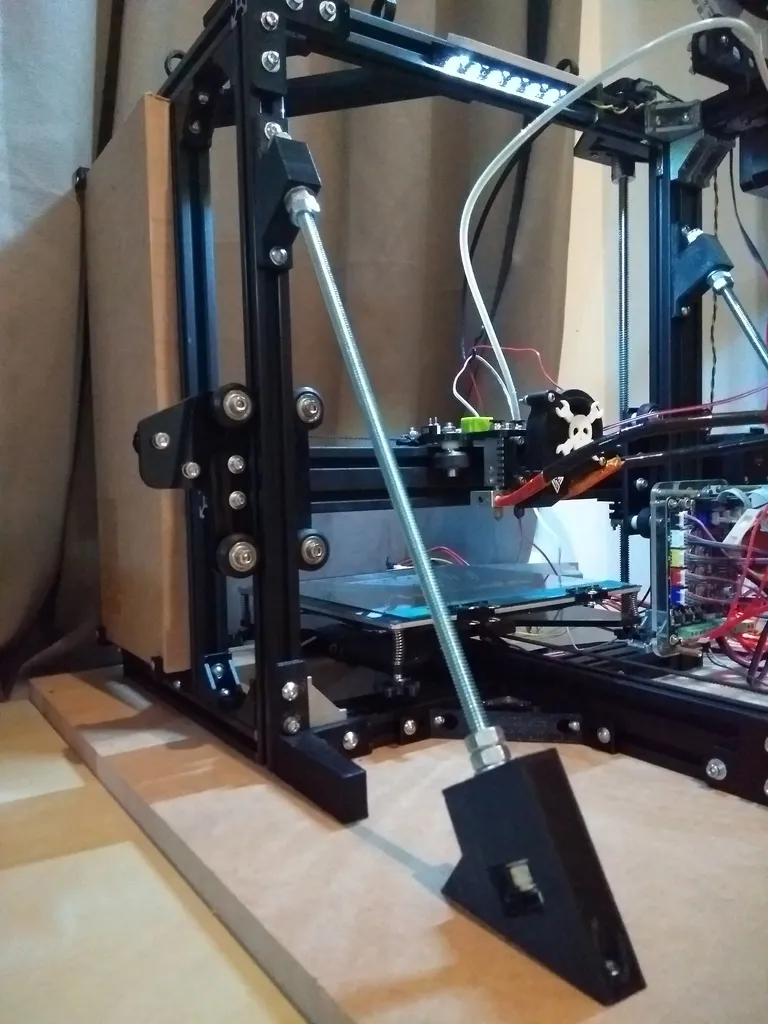

The Tevo Tarantula is a popular 3D printer, known for its affordability and ease of modification. However, like any budget-friendly machine, the stock components can be improved upon. This guide focuses on five key upgrades for the Z-axis rod, a critical component for vertical movement and print quality. By implementing these secrets, you can dramatically enhance your Tevo Tarantula’s performance, resulting in more accurate and visually appealing prints. The Z-axis, which controls the vertical movement of the print head, is particularly susceptible to issues like wobble, layer shifting, and inconsistent layer adhesion. Upgrading this area is crucial to improve your 3D printing experience and output.

Why Z-Rod Upgrades Matter

Upgrading the Z-rod on your Tevo Tarantula directly impacts the quality of your prints. A stable and accurate Z-axis is fundamental to producing high-quality 3D prints. Instability in the Z-axis leads to several common problems: layer shifting, where layers are not perfectly aligned; Z-wobble, characterized by vertical lines or artifacts on the print’s surface; and poor layer adhesion, where layers don’t bond properly. These issues can ruin prints and waste filament, time, and effort. Investing in Z-rod upgrades can significantly improve your prints, ensuring better accuracy, smoother surfaces, and overall enhanced print quality. Ultimately, these upgrades improve the overall reliability and satisfaction of the printing process.

Investing in these upgrades is a smart move for any Tevo Tarantula owner looking to achieve professional-grade prints. The small investment in better components and improved setup can drastically enhance the reliability and output quality of the printer. Moreover, it contributes to a more satisfying and less frustrating 3D printing experience. This is not just about making your prints look better, it’s about creating a more reliable, predictable, and enjoyable hobby or workflow.

Understanding the Importance of Z-Rod Stability

The Z-rod’s primary function is to provide vertical movement to the print head, allowing the printer to build layers. Stability in this axis is paramount for print quality. Any play or wobble in the Z-axis translates directly into imperfections in the printed model. This means that every movement of the print head, no matter how small, must be precise and controlled to guarantee the final object matches its intended design. Even slight deviations can lead to visible layer lines, inaccurate dimensions, and overall poor print quality. The stability of the Z-rod is therefore critical to achieving clean and accurate 3D prints.

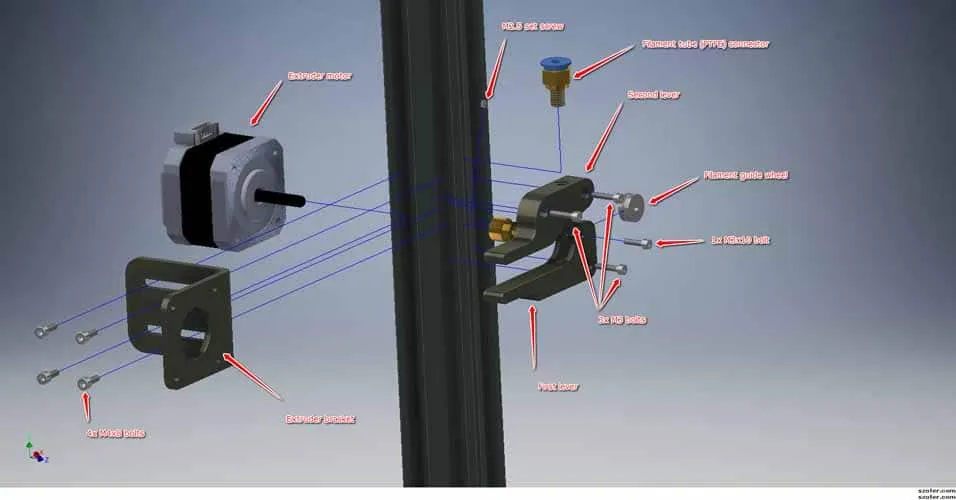

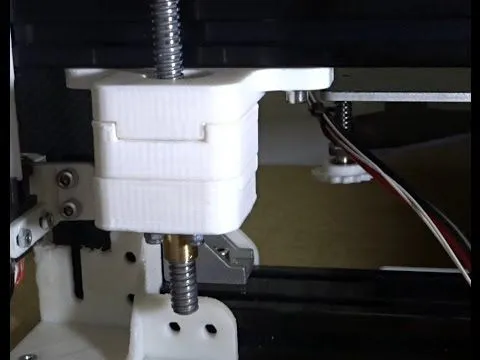

Secret 1 Upgrading Z-Rod Couplers

Z-rod couplers are the connectors that join the Z-rod to the stepper motor. The stock couplers on the Tevo Tarantula are often made of flexible plastic or rubber, which can introduce play and wobble. Upgrading to rigid, high-quality couplers is one of the most impactful upgrades. These upgrades enhance the coupling between the motor and the Z-rod. Replacing the flexible couplers with more rigid ones can dramatically reduce play and vibration, leading to significant improvements in print quality.

The Benefits of Upgraded Couplers

Upgraded couplers offer several benefits. The reduced wobble minimizes the effect of vibrations, which directly translates into smoother surfaces on your prints. By minimizing play, the Z-axis moves more precisely, resulting in more accurate layer placement and dimensional accuracy. Furthermore, better couplers provide a more direct and efficient transfer of power from the stepper motor to the Z-rod. This can lead to faster print speeds and improved overall print quality. A high-quality coupler ensures the motor’s rotations are accurately translated into vertical movement, thus reducing layer inconsistencies.

Choosing the Right Couplers for Your Tevo Tarantula

When selecting couplers, consider material and design. Metal couplers, such as those made of aluminum or brass, are generally more rigid and durable than plastic ones. Flexible couplers, while useful for minor misalignments, can introduce unwanted play. Look for couplers designed specifically for 3D printer Z-rods, and ensure they match the motor shaft and Z-rod diameter. Make sure the coupler has the appropriate set screws to secure it firmly to both the motor shaft and the Z-rod itself. Consider the reviews from other Tevo Tarantula owners to get an idea of which couplers perform best in real-world use.

Secret 2 Improving Z-Rod Bearings

The bearings that guide the Z-rod play a crucial role in its smooth and precise movement. The stock bearings in the Tevo Tarantula might not always provide the best performance. Upgrading these bearings can significantly reduce friction and improve the Z-axis’s overall stability. Switching to higher-quality bearings is a straightforward and cost-effective upgrade, that yields improvements in print quality, smoother operation, and reduced noise. Good quality bearings reduce the resistance the Z-axis faces during its movement.

The Role of Bearings in Print Quality

Bearings are essential for ensuring that the Z-rod moves smoothly and without excessive friction. Lower friction means the Z-axis motor can move more precisely, resulting in more accurate layer placement. If the bearings are worn or of poor quality, the Z-rod may wobble or stick, leading to inconsistent layer heights and other print defects. High-quality bearings minimize these issues, contributing to smoother prints and improved dimensional accuracy. The better the bearings, the more consistently the print head will move, leading to a substantial improvement in print quality.

Types of Bearings and Their Impact

Several types of bearings are available for 3D printers. Linear bearings, like LM8UU bearings, are a common upgrade. These bearings are designed to provide smooth, low-friction linear motion. Another option is to replace the stock bearings with ball bearings. The choice depends on factors such as cost, noise levels, and desired performance. Consider sealed bearings, as they offer added protection against dust and debris, extending the lifespan of the bearings and maintaining smooth operation. Research the different types of bearings to find the best fit for your specific printing needs and budget.

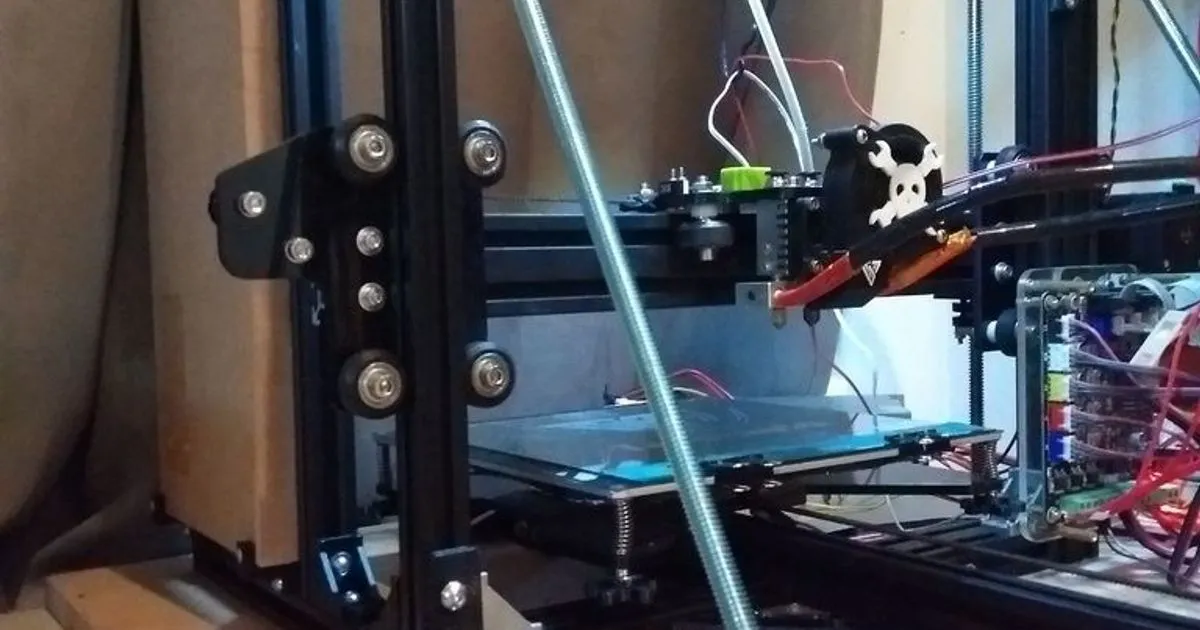

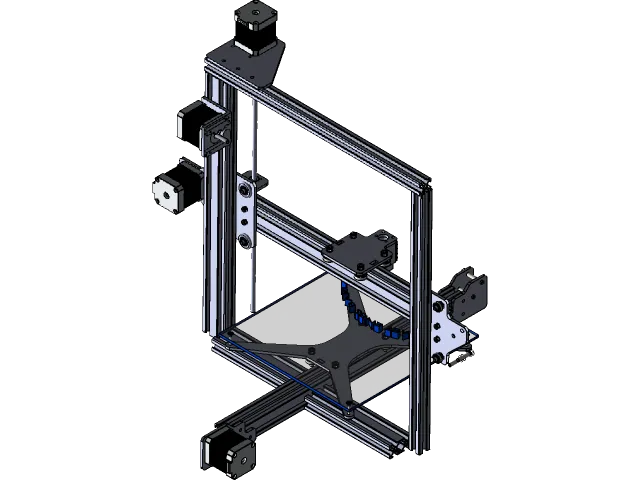

Secret 3 Reinforcing the Z-Axis Frame

The frame of the Tevo Tarantula, particularly the Z-axis structure, can be susceptible to flex, especially during rapid movements. Reinforcing the frame is a crucial step for improving stability and print quality. A more rigid frame minimizes vibrations and ensures the Z-axis remains stable throughout the printing process. By reinforcing the frame, you can significantly improve the accuracy and quality of your 3D prints, and extend the printer’s lifespan. This upgrade will have a cascading effect on the quality of prints.

Addressing Frame Flex and Its Effects

Frame flex manifests in various ways, including Z-wobble, layer shifting, and inconsistent layer adhesion. This flex is especially pronounced during faster print speeds or when printing tall objects. The consequences of frame flex directly affect the quality of the print. The result may be unsightly layer lines or complete print failures. Addressing and eliminating flex ensures consistent and precise movement of the print head along the Z-axis. The objective is to eliminate any unwanted movement that can ruin the print.

Reinforcement Techniques for Enhanced Rigidity

Several reinforcement techniques can be employed to stiffen the Z-axis frame. Adding brackets, such as corner brackets, to the frame can increase its rigidity. Using stronger materials for the frame, such as thicker aluminum extrusions or carbon fiber rods, can make the frame much more stable. Ensure all bolts are tightened securely. A combination of these methods, coupled with precise alignment, will improve frame stability. Make sure the reinforcements do not impede the printer’s movement and maintain accurate alignment.

Secret 4 Optimizing Z-Rod Alignment

Precise Z-rod alignment is fundamental for consistent print quality. Misalignment of the Z-rods can introduce a host of issues, from Z-wobble to layer shifting. Proper alignment is vital to the overall performance and accuracy of the printer. Regular checks and adjustments are essential to maintain print quality. Correctly aligning the Z-rods ensures they move in perfect parallel motion, guaranteeing the print head moves smoothly and precisely along the vertical axis.

The Importance of Proper Z-Rod Alignment

Misaligned Z-rods cause numerous print defects. If the Z-rods are not perfectly parallel, the print head will tilt as it moves up and down, resulting in an uneven print surface. This misalignment can lead to layer shifting and other print quality issues. Accurate alignment ensures the print head moves smoothly, avoiding any unwanted tilting or friction. Correct alignment provides a solid foundation for achieving high-quality prints. It’s an essential step in ensuring the printer delivers accurate and consistent results.

Step-by-Step Alignment Guide

Proper Z-rod alignment typically involves a few key steps. First, ensure the printer is level. Use a level tool to verify that the printer is sitting evenly on the surface. Next, loosen the Z-rod couplers slightly. Gently raise and lower the print head, checking for any binding or friction. If any friction is detected, adjust the couplers and Z-rods until the movement is smooth. Carefully tighten the couplers. Double-check the alignment after tightening. Perform several test prints to confirm the adjustments. Regularly re-check the alignment to ensure the best performance.

Secret 5 Fine-Tuning Firmware Settings

The firmware on your Tevo Tarantula controls many aspects of the printer’s performance, including the Z-axis motor control. Fine-tuning these settings can optimize the performance of your Z-rod upgrades, leading to even better print quality. The proper settings make the most of the hardware upgrades. The proper tuning can further improve the print quality and consistency.

Firmware’s Role in Z-Rod Performance

Firmware settings dictate how the printer’s motors and other components behave. For the Z-axis, firmware parameters such as steps per mm and acceleration can significantly impact print quality. Incorrect settings can cause Z-wobble, layer shifting, and other issues. Optimizing the firmware settings can improve the printer’s response to commands and refine print quality. Correct firmware configuration is vital to maximize the benefits of your Z-rod upgrades.

Recommended Firmware Tweaks for Z-Rod Upgrades

Several firmware parameters can be optimized to improve Z-rod performance. Adjusting the steps per mm value ensures the Z-axis moves the correct distance. Reduce acceleration and jerk settings. These settings control how quickly the motors accelerate and decelerate, thus reducing vibrations. Regularly calibrate your printer after any hardware modifications or firmware adjustments. Remember to save the new settings to the printer’s EEPROM to prevent losing your custom configuration. Experiment with different settings to find what works best.

By following these five secrets, you can significantly enhance the performance of your Tevo Tarantula’s Z-axis and achieve higher-quality 3D prints. These upgrades, when implemented correctly, can dramatically improve your printer’s overall performance. It’s not just about upgrading components; it’s about creating a more stable and reliable 3D printing experience. Regular maintenance and a continuous learning approach are important in improving your prints further.